Industry

Industry

Industry

Industry

Industry

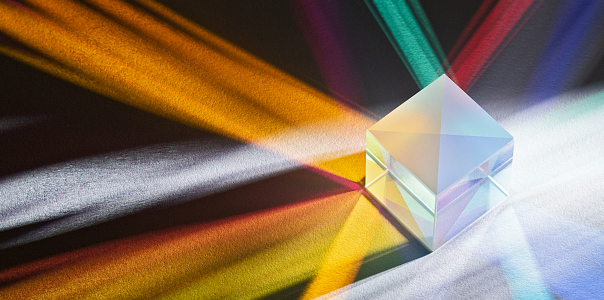

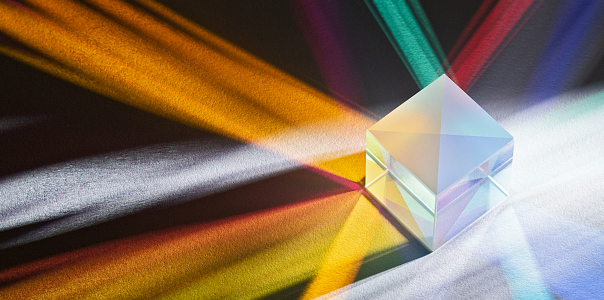

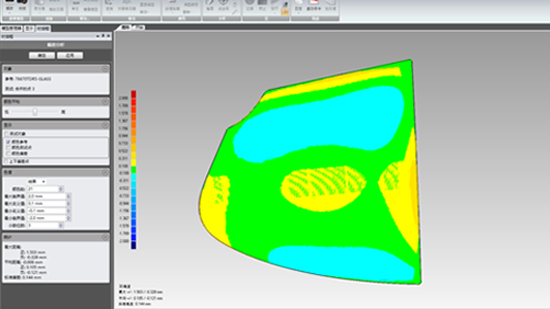

With the increasing precision and quality requirements for vehicle assembly year by year, the precision requirements for components are also getting higher. The control of incoming part accuracy, typically managed through three-coordinate sampling inspection, is inefficient and inaccurate, failing to meet the assembly demands of car manufacturers that produce a vehicle within minutes, particularly for safety-critical components such as the car's front windshield. Our company has successfully developed the first online glass surface inspection equipment in China by utilizing our proprietary optical algorithm technology, combined with our self-developed industrial laser measuring probes. This equipment can complete the scanning of large-sized glass surfaces within seconds, output point cloud data, and determine the inspection results, while also aiding manufacturers in process improvement and enhancement. The high efficiency and stability of laser technology make it suitable for online factory integration without interference from other hardware. It is applicable both for manufacturers to control process quality and as an incoming inspection device for car manufacturers.

The optoelectronics industry is characterized by its labor intensity, with a significant workforce primarily allocated to product quality inspection. There is an elevated requirement for skilled technicians who necessitate specialized training and a guaranteed minimum duration of work experience. The industry faces extremely high employee turnover rates, leading to substantial labor costs for businesses. Additionally, the reliance on manual inspection cannot ensure the consistency of product quality. In response to these challenges, particularly for the surface smoothness inspection of optical components, our company has successfully implemented online inspection of micro-cylindrical mirror surface quality using our proprietary optical algorithm technology. The software's data analysis capabilities further assist the production side in making informed process improvements. We supply renowned domestic enterprises with online inspection equipment for the surface smoothness of micro-convex cylindrical mirrors, capable of detecting various types of defects. We are the first domestic supplier of such online inspection equipment for micro-cylindrical mirrors.

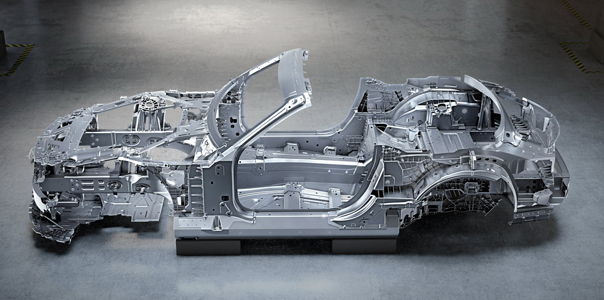

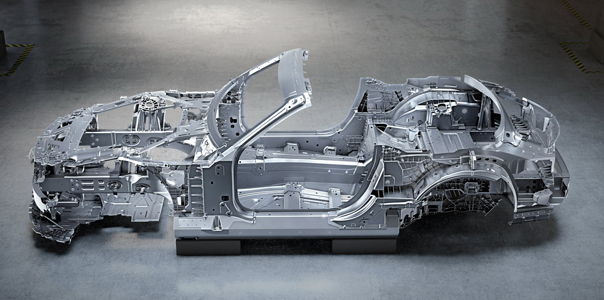

Visual inspection of steel plate defects is a method that utilizes machine vision technology to detect and categorize surface defects on steel plates. This includes:

1. Surface defect detection: Defects such as cracks, bubbles, inclusions, laps, and rust may exist on the surface of steel plates. Machine vision technology can quickly and accurately detect these defects, and classify and mark them accordingly.

2. Dimension measurement: Accurate measurement of steel plate dimensions is crucial for manufacturing. Machine vision technology enables high-precision measurement and calibration of steel plate dimensions, including parameters such as length, width, and thickness.

3. Shape recognition: The shape and contour of steel plates also significantly affect the quality and performance of products. Machine vision technology allows for rapid identification and classification of steel plate shapes, ensuring products meet specifications.

4. Character recognition: Steel plates may bear various identifiers, such as product models, production dates, and manufacturers' information. Machine vision technology can quickly and accurately recognize these characters and classify and extract them.

5. Defect cause analysis: Machine vision technology can provide detailed analysis and recording of steel plate defects, including information on the type, location, size, and quantity of defects. This helps manufacturers identify the causes of defects and take measures to improve production processes.

As an efficient automated inspection method, visual inspection of steel plate defects can improve production efficiency and quality, reduce production costs and scrap rates, and has broad application value in fields such as steel, automotive, and construction.

- 022-87459086 13404662299

- Huayuan Xinmao Science and Technology Park, Tianjin China.

- louis.liu@deepoptics.net

- zhaopeng@deepoptics.net

Trusted Optics R&D Service Provider!